Efficient Solar Panel Interconnect Ribbon for Enhanced Energy Connectivity

Description

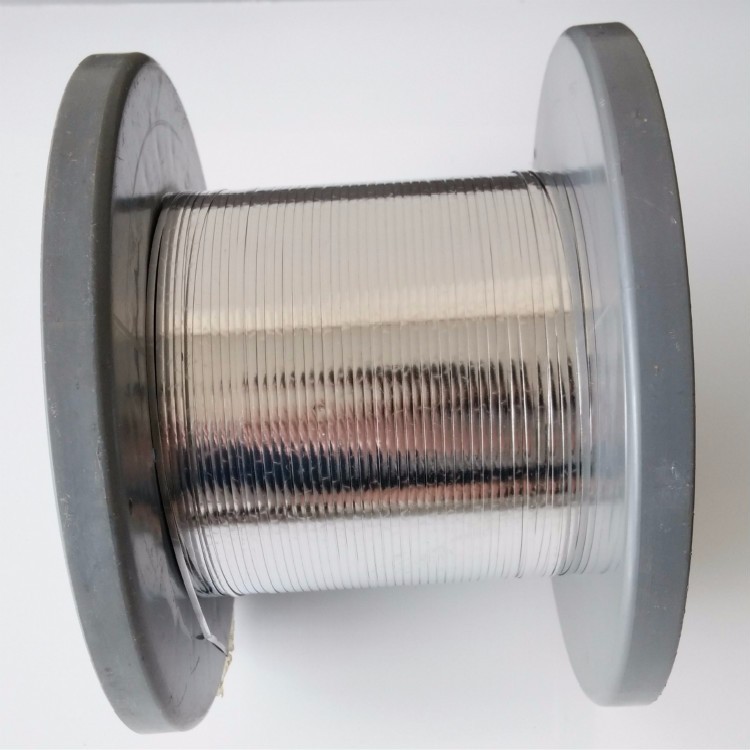

Spooling Packing Tabbing Wire/PV Ribbon for Machine Automatic Soldering Solar Cells

Solar interconnect ribbon is a kind of fine high-carbon steel wire of high strength, high hardness, and high wear resistance. It is used as the carrier for multi-wire sawing to cut super-hard crystalline materials, such as silicon, gallium arsenide, indium phosphide, silicon carbide and crystal.

specifications

Solar interconnet ribbon General Introduciton

| 1. Base Copper Parameter | |

| Base copper trademark | Oxygen-free copper C1022 |

| Copper purity | Cu≥99.97% |

| Electrical conductivity | ≥100% IACS |

| Resistivity | ≤0.01724 Ω·m m2/m |

| 2. Coating Thickness and Composition(can customize according to clients' technical requirement) | |||

| Coating Alloy Type | Coating Composition | Coating Thickness each side (mm) | Coating Thickness Tolerance (mm) |

| Leaded | Sn60% Pb40% | 0.01-0.04 | ±0.01 |

| Sn62% Pb36% Ag2% | 0.01-0.04 | ±0.01 | |

| Lead-free | Sn97% Ag3% | 0.01-0.04 | ±0.01 |

| 3. Mechanical Characters for Commen Spool Product | |

| Elongation | ≥15% |

| Tensile strength | ≥150MPa |

| Side camber | L≤8mm/1000mm |

| 4. Physical Dimension and Tolerance of Common Spool Product | |||

| Thickness range | 0.045-0.35mm (can customize according to clients' technical requirement) | ||

| Thickness tolerance | ±0.02mm | ||

| Width range | 1.0-2.5mm (can customize according to clients' technical requirement) | ||

| Width tolerance | ±0.08mm | ||

| Common Specification of Tabbing Ribbon(mm) (Spool Package) | |||

| 0.18×2.0 | 0.22×2.0 | 0.24×2.0 | 0.27×2.0 |

| 0.20×1.5 | 0.23×1.5 | 0.25×1.5 | 0.30×1.5 |

| 0.20×1.6 | 0.23×1.6 | 0.25×1.6 | 0.30×1.6 |

| 0.2×1.8 | 0.23×1.8 | 0.25×1.8 | 0.30×1.8 |

| 0.2×2.0 | 0.23×2.0 | 0.25×2.0 | 0.30×2.0 |

Storage Conditions and Shelf Life

Tinned copper ribbon should be stored in dry and ventilated room, where should be no acid, alkail, or harmful gas and the indoor relative humidity should not exceed 60%. Place it horizontally while stacking and avoid the carton extrusion&vertical placement, meanwhile, the stacking quantity of same products not exceed five layers or 1 ton. The shelf life can be up to six months since the production date.

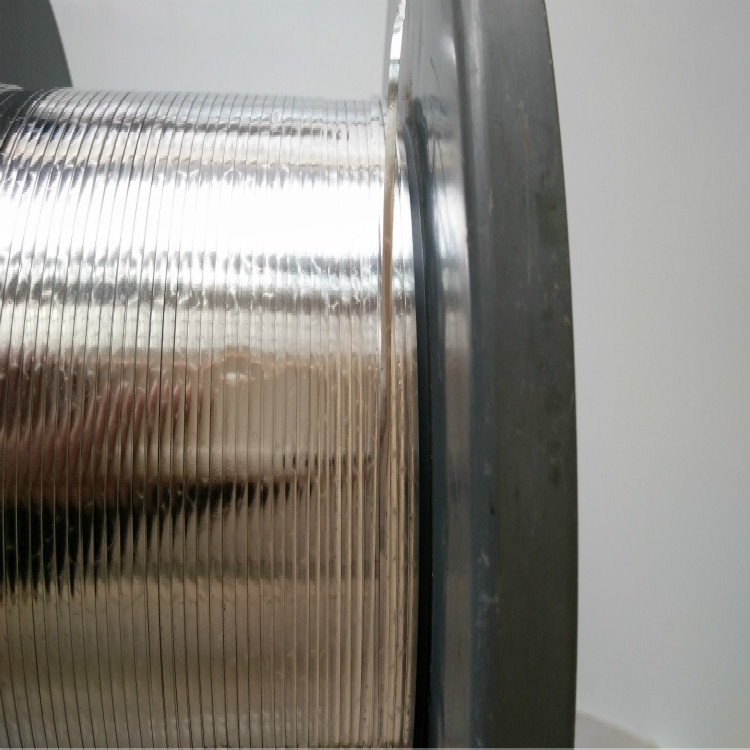

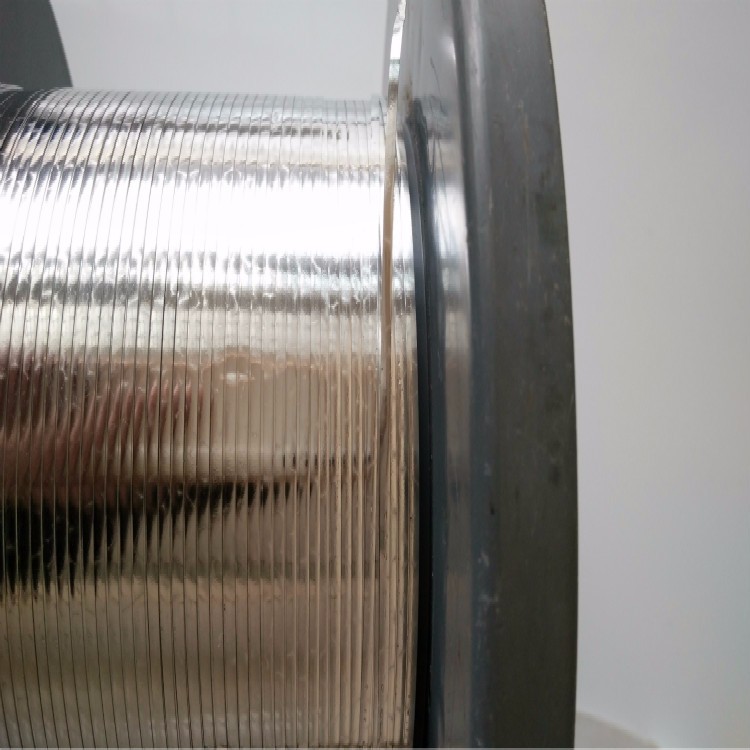

Product Display