High Performance Solar Junction Box for Maximum Efficiency

Description

Features and Applications:

The item (tin coated copper welding ribbon) is based on size of Width*Thickness: 1.5*0.2 mm (it also can be 1.5-2.5mm * 0.08-0.25mm as your option),

sale as per lot, 2kgs/lot.

if you want buy more or less quantity, pls contact us, we will correct the price and freight cost for you.

About PV busbar Ribbon

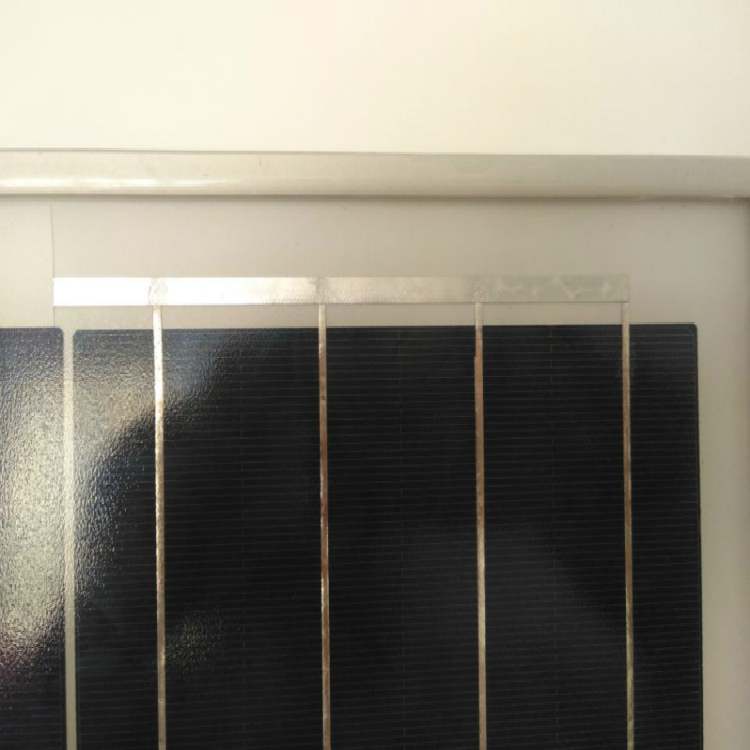

PV ribbon is composed of Copper and coating alloys, and divided into Tabbing Ribbon and Bus bar ribbon.

Tabbing Ribbon: it is commonly connects the positive and negative sides of the cells in series.

Bus bar Ribbon: it is concentrate the cell stringing into junction box and channels electrical current.

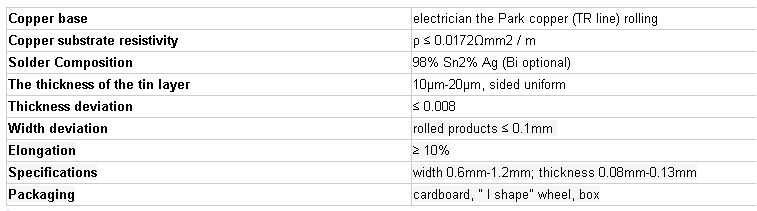

specifications

1) welding ribbon for big power solar panel:

| Copper base | electrician Park copper (TR line) rolling or T2 copper tape slitting |

| Copper substrate resistivity | ρ ≤ 0.0172Ωmm2 / m |

| Solder Composition | 62% Sn36% Pb2% Ag; 60% Sn40% Pb; 96.5% Sn3.5% Ag (Bi optional) |

| The thickness of the tin layer | 10μm-40μm, sided uniform |

| Thickness deviation | ≤ 0.008 |

| Width deviation | the rolled products ≤ 0.1mm; slitting Commodities ≤ 0.005mm |

| Elongation | the soft state ≥ 20%; semi-soft state ≥ 15% |

| Specifications | width 1.5mm-2.5mm; thickness 0.08mm-0.25mm. (here is 1.5*0.2 mm) |

| Packaging | cardboard, " I shape" wheel, box |

| Suitable for DIY solar cell and solar panel, also suitable for machine automatic welding middle without decapitation; crop for customers L | |

2) welding ribbon for epoxy solar panel etc. mini solar panel:

Storage Conditions and Shelf Life

Tinned copper ribbon should be stored in dry and ventilated room, where should be no acid, alkail, or harmful gas and the indoor relative humidity should not exceed 60%. Place it horizontally while stacking and avoid the carton extrusion&vertical placement, meanwhile, the stacking quantity of same products not exceed five layers or 1 ton. The shelf life can be up to six months since the production date.

Product Display