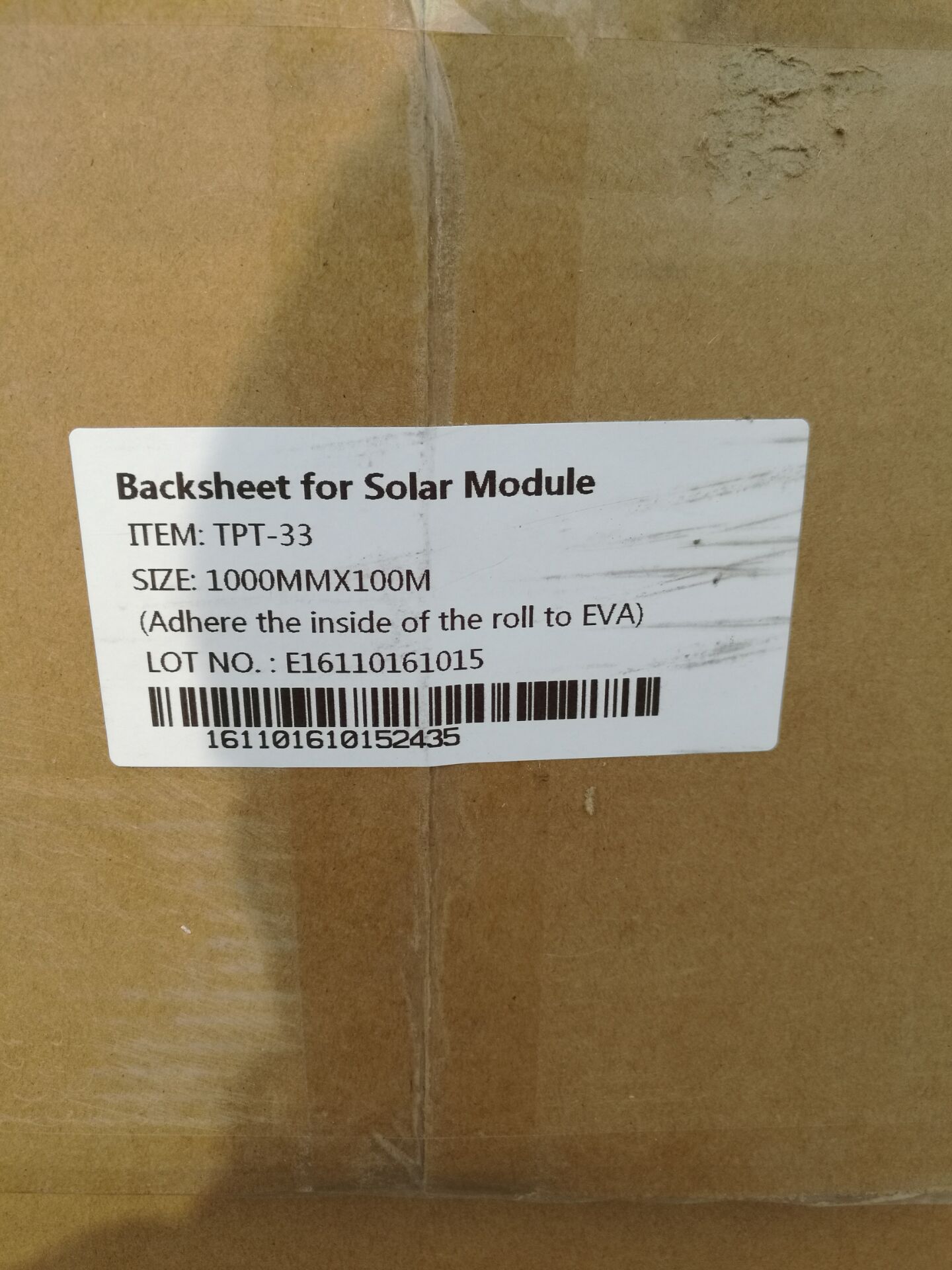

Tpt Backsheet For Solar Panel Encapsulation

Description

Tpt Backsheet For Solar Panel Encapsulation Specification (TPT/TPE/PET Backsheet)

Thickness: 0.3mm. 0.28mm. 0.25mm. 0.2mm

(2) Width: Common width: 550mm.680mm, 810mm, 1000mm.

(3) Length: 100m per roll.

Products Application

Outdoor architectural; Curtain wall; Automobile glasses; Bullet-proof glass; skylight; doors and windows and other outdoors decorations etc.

specifications

|

ITEM |

UNIT |

TPT-30 |

|

|

Tensile strength |

N/cm |

≥ 110 |

|

|

Elongation ratio |

% |

130 |

|

|

Tearing strength |

N/mm |

140 |

|

|

Interlaminar strength |

N/5cm |

≥25 |

|

|

Peeling strength |

TPT/EVA |

N/cm |

≥20 |

|

TPE/EVA |

≥50 |

||

|

Weightlessness (24h/150degree) |

% |

<3.0 |

|

|

Shrinkage ratio(0.5h/150degree) |

% |

<2.5 |

|

|

Water vapor transmission |

g/m224h |

<2.0 |

|

|

Breakdown voltage |

KV |

≥25 |

|

|

Partial discharge |

VDC |

>1000 |

|

|

UV aging resistance(100h) |

— |

No discoloration |

|

|

Life |

— |

More than 25 years |

|

Core Technology

High Fluorine:

Created the interconnected penetrate technology of high fluorine symplectite, with organic integration of the multi-fluoride raw material——Enhance the anti-ageing capability, improves weather resistance

Precision Coating:

Ripple-free high-precision coating technology makes coating of the surface smooth, and the uniform consistent——Enhance the density of the surface coating, improves electrical insulation properties

Nano:

Nano-titanium silicide plasma processing techniques to enhance durable surface energy——Upgrades package compatibility, improves adhesion of EVA and silicone binding agent

Application Advantages

1. High Weather Resistance

Through the accelerated ageing test of double-85 for 1000 hours, there will be non-delamination, non-cracking, non-foaming, as well as non-yellowing, no embrittlement after ageing by artificialultraviolet radiation exposure (QUVB) test for 3000 hours.

2. High Security

Security grade has passed the flame-retardant UL94-V2 flame-retardant grade. The UL flame spread index is less than 100, which effectively guarantees the module security features.

3. High insulation

TUV Rheinland of PD>=1000VDC (based on HFF-300), whichcan avoid electrical arcing module.

4. High Water Vapor Resistance

By infrared water vapor permeability tester, the water vapor permeability rates≤1.0g/m2.d.

5. High Adhesion

After the nano-plasma treatment, the surface energy of high fluoride levels can last 45mN/m or more within six months.

6. High-end Match

Suitable for large-scale photovoltaic power plants with the crystalline silicon cells module package.

7. High Compatibility

Good compatibility comes from the bonding with the other packaging materials of module.

8. High Efficiency

For its double-sided adhesion, there's no need to distinguish the backsheet's positive and negative when components packaging, which brings convenience for technicians.

9. High Flexibility

The adhesive data of the bone package for the module and EVA could be adjusted as per the clients'requirements.

Performance Improvement

Our TPT symplectite coatings contain highly dispersed nano titanium silicide and high thermal conductivity materials, which greatly improve the High-FluoroCocrystal solar cell backsheet performance.Mainly in:

High Scratching Resistance

The high scratching resistance gets rid of these shortcomings of traditional coating, such as the surface of anti-scratch performance is poor, during the coating operation it is easy to get scratches or peel off, thus affecting the backsheet anti-ageing properties, etc.

High Reflectivity

Improves the light's second reflection, enhances module output power, and increases the competitiveness of client module.

High Heat Dissipation

Improves power generation efficiency of the backsheet by accelerating heat dissipation.

Product Display